Overview

Pushpak specialises in electrochemical processes for onboard satellite application. The current facility in Jalahalli have been delivering products with 100% success, and zero defect since more than 15 years. Our upcoming state-of-art facility in aerospace park, devanahalli, will take production to a mass scale with NADCAP and Aerospace certification.

Our technical manpower is certified from ISRO, on delivering high end products that endure in demanding environments. We are also the certified electrochemical supplier for all divisions of ISRO and their suppliers, HAL, L&T, Astra, Centum and many more for over 14 processes.

Our upcoming facilities and ever improving technical expertise have enabled us to become one of the ISRO certified and qualified electrochemical processor.

14 process (Certificates)

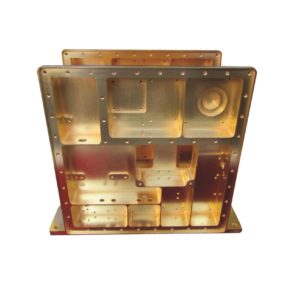

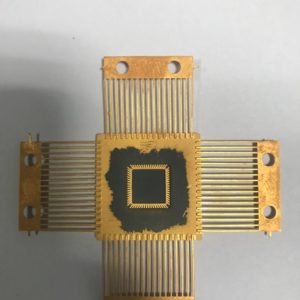

Some of the defined processes undertaken by us are black anodizing, inorganic black anodizing, normal anodizing, hard anodizing, selective anodizing and gold plating for spacecraft onboard components for satellite applications.

- Normal Anodizing

- Black Anodizing

- Hard Anodizing

- Chromic Acid Anodizing

- Electroless Nickel Plating

- Gold Plating on Aluminium Alloys

- Gold Plating on Invar

- Gold Plating on Stainless steel

- Gold Plating on Kovar

- Thermal Black Painting

- Silver Plating on Aluminium Alloys

- Chromating (on Aluminium Alloys)

- Thermal aeroglaze (Z-306) Black painting on Aluminium, Invar, SS & Titanium

- Electroless Nickel plating on Aluminium, Invar, SS & Titanium

With support from ISRO, we have been the pioneers for developing Ultra High Solar Absorptance process in India.

State-of-the-art facilities and ever-improving technical expertise have enabled us to become one of the ISRO certified and qualified Anodizer in India.

We also specialise in Anodising of Aluminium and Megnesium Alloy for Spacecraft Components. Anodizing - Inorganic black coloured Telescope Cylinder of astrosat space craft to ISRO Team in 2008 which was done for the first time in India.

We are a 4 National awards winner in multiple areas. We follow stringent processes in our production unit. Only branded and certified chemicals are used in the process. Every material that comes out of the unit, comes with an Inspection report and Certificate of Conformance(COC). We follow COC based process throughout the product lifecycle. Furthermore, a full-fledged research unit along with production unit, is a boon to customers who would like to customise.